November 5, 2023

In my last post I referenced every time I started to my make a little progress on my BSA Gold Star something got in the way. Immediately after finishing the head work on the Gold Star, my Triumph twin, which has had an ongoing issue of fouling plugs, hit a point where too much oil was entering the cylinder. It was time after 10 years of avoiding this issue to deal with it and find out the cause.

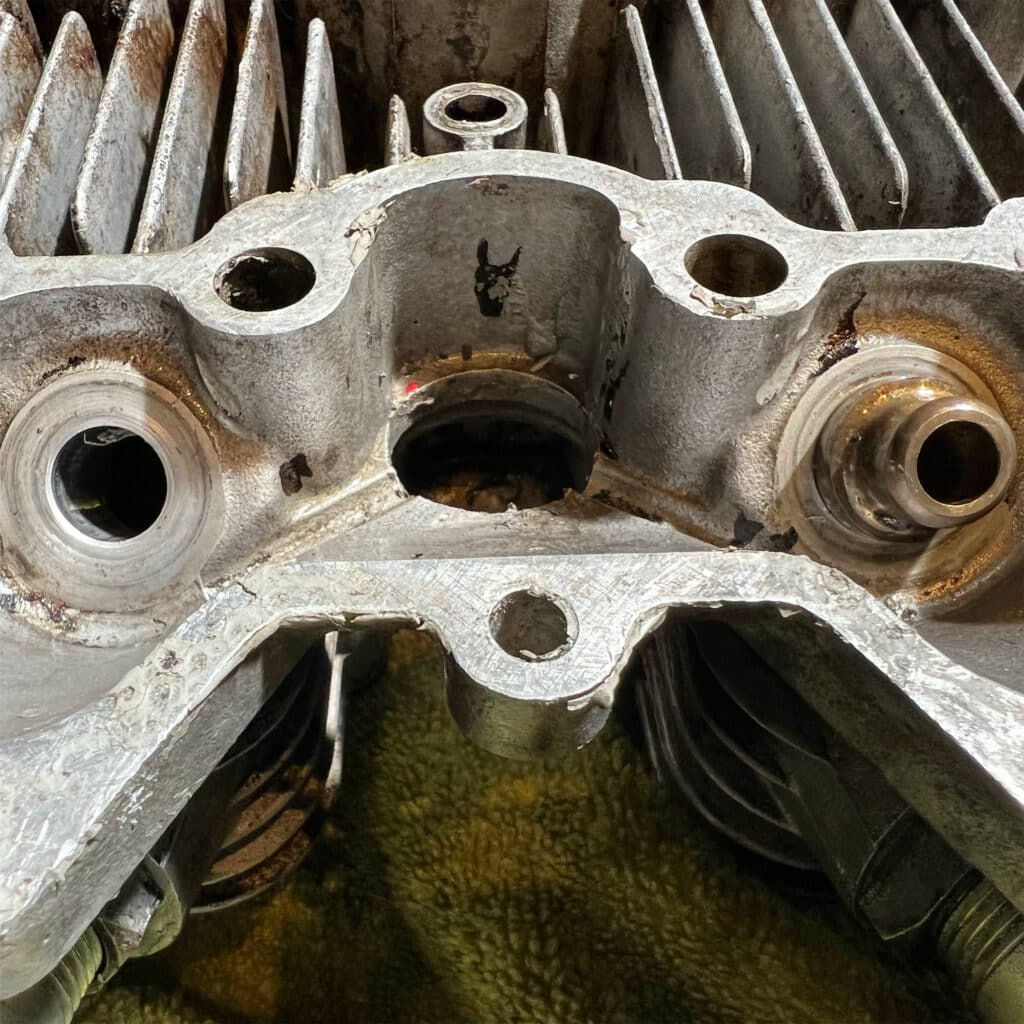

I removed the head and as I started the process of removing the valves, one of the guides just fell out of the head! The remaining guides were pushed out easily by hand with almost no press fit at all. The head showed signs of some less than desirable repairs in the past long before I got it, as well as some scaring from what looks like a 7/16 or 10mm nut. I used some Scotchbrite style polishing wheels on a drill to remove as much of the scarring as possible in the efforts to make a clean seal and to minimize any potential for a cylinder hot spot which can end an air cooled, or really any engine quickly.

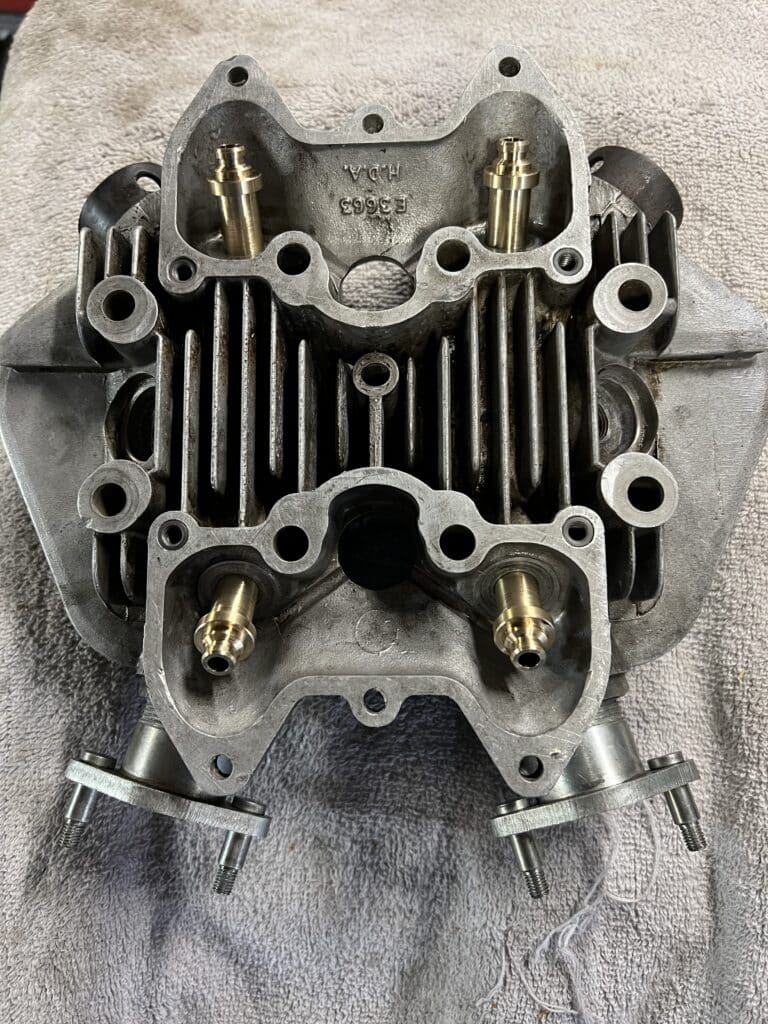

I had been using this particular Triumph to commute downtown to my office on days I did not have to ferry kids around. The easiest thing I acquired to get me up and going quickly, were new 6mm valves, beehive springs, and new retainers/keepers in a kit from Kibblewhite in Pacifica, CA.

I was lucky given the supply issues at the time, that I was able to purchase .015 oversize Kibblewhite guides already machined for their oil seals. We made another Delrin tapered plug and used an adjustable reamer to make the head round and uniform for the new guides. Then we machined the oversized guides down until we had just under a .002 press fit for the new guides to press into the head. By heating the head and freezing the guides, we accomplished this and then we fitted the valves to the guides with a valve guide hone. We then were ready for the valve grinding.

A trial fit of the new valves revealed on one intake valve, there was a very butchered valve seat. That would have set the valve very low on the valve seat after grinding which probably would have caused other problems. The only way we could see a way to salvage this issue would be to remove the seats, install new ones and start over. I made a trip to a machine shop in Petaluma, and after a few days of waiting, I was back in business. New seats! A shocking difference now with this motorcycle back together and running in a way I have never experienced it.

Comments