Originally written: 12/5/2021

Blog Publication Date: 8/12/23

I wrote this article for publication for a website called “The Return of the Café Racers,” a couple of years ago. Geoffrey read my story, edited it to his liking and then published it. I am re-writing it now for this blog in the interest of adding context to the other Rickman articles in our blog. Parts of this article are similar and some parts are new. The published article can be seen here:

https://www.returnofthecaferacers.com/triumph-cafe-racer/kosman-rickman-t120/

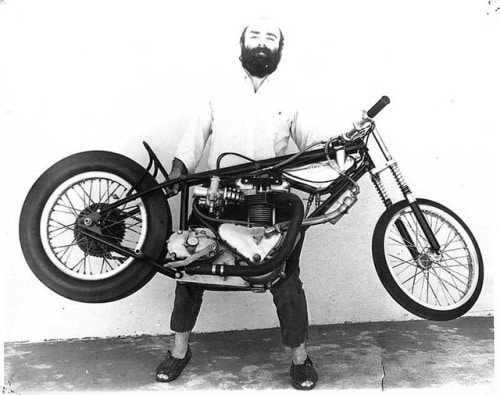

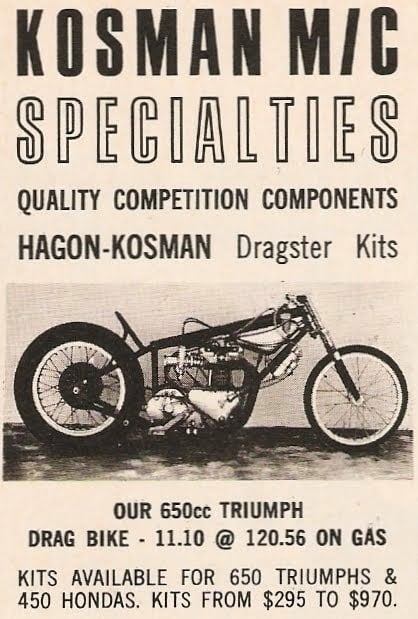

This bike started its life around 1970 at Kosman Specialties, where I worked for about three years, from 1968 to 1971, while I was in college. Sandy Kosman designed and manufactured many different parts, including alloy oil tanks, hubs, disc brakes, oil filter carriers, and many other parts. He also built drag racing bikes and made frames in conjunction with Alf Hagon. Kosman bikes held several records both for gas and fuel drag racing. Kosman Specialties went on to become one of the most innovative businesses in motorcycle racing. The photos below show Sandy picking up one of his drag bikes, and an ad for Kosman drag bikes from around 1969 or so. Sadly, Sandy died last year and was recently inducted into the Motorcycle Hall Of Fame.

I did many jobs while working there from machining parts to lacing wheels, to bike repairs and builds. I laced and trued almost 3,000 wheels for the drag bike kits Kosman sold, mostly 17” front wheels, sometimes 16 per day, until it became so repetitive I passed the job on to another employee. Kosman’s shop was a hub for racers and their machines, and we worked on almost everything. There were many spare parts in the shop on shelves, and frames hanging up too.

One of the employees (Bradley) decided to put together a bike for himself from a 1969 Rickman Métisse frame, tank, and Avon seat fairing that Sandy sold him. There was a 1967, T-120TT Special bottom end on a shelf without barrels or head that was built by a guy named Carl Rhodes and set some records as a 650cc motor. How it ended up in Kosman’s shop is unknown to me but I helped Bradley some on the build of his bike. He got a hold of a set of 800cc barrels, bored them .060 over, a TR6 head which was modified, cc’d and assembled with the lower end. The engine had PM 1060 racing cams (now Megacycle Cams), drilled and lightened parts, was balanced, and then fitted with a Joe Hunt/ARD/Fairbanks Morris magneto.

The parts for this bike were often used pieces lying around the shop and purchased from Kosman. The front end was a set of Ceriani GP35 forks and a Fontana magneisum 210mm four-leading shoe brake, laced to a Borrani WM2 19” rim. The rear wheel was a stock Triumph brake with a drilled and chromed backing plate, laced to an Akront WM3 18” rim. Dunlap K-70 tires were mounted front and rear. Along the way something happened. Either Bradly needed money or something happened with him and Kosman or ???, but he had to sell the bike. It wasn’t street legal with straight TT Pipes and no lighting but when we got it running at the shop and rode it around the block, everyone who rode it was amazed at how powerful this bike was. It had the standard one-gallon Rickman motocross tank and weighed in at only 295 lbs. with oil and gas!

I had my own 750 BSA Spitfire Hornet but I told my good friend Bill Truscott about this bike that was now being sold and he jumped on it and bought it that day. When Bill took possession of the bike, he decided he wanted to ride it on the road. This meant he would need lights, mirror, horn, and a way to silence the motor, which was much louder than a stock TT Special because of the larger displacement and especially because of the cams allowing in a larger amount of gas/air. I welded up a pair of Kosman spun reverse-cone megaphone pipes, with home made wrapped fiberglass inserts for the bike, wired the lighting, installed a mirror and horn and we went to DMV for registration. It was complicated because DMV would not call the bike a Triumph. They said it was a “Special Construction” because of the Rickman Frame. After many hoops to jump through, the California Highway Patrol assigned the frame and motor with special construction numbered tags and along with the receipts from Kosman, the bike got titled and registered.

The bike had several issues. The easiest to deal with was the exhaust. The pair of silencers I made worked for the DMV and CHP, but the performance was cut in half. They were horrible so Bill took them off and rode with open exhaust. We usually rode our bikes together by trucking them on weekends out to fairly deserted back roads outside San Francisco where we less likely to be pulled over for noise. The one-gallon tank limited the rides to about 30 miles so we often rode in a figure eight pattern and refueled at my truck. The bike was very hard to start when warm and especially hard to start when cold, so we often towed it with a rope behind my truck if there wasn’t a good long hill to bump start it. I suspected something wasn’t right in the magneto but it seemed to run OK once it finally fired. We often traded bikes for part of our rides and Bill rode my BSA and I rode his Triumph. I had a fairly tricked out 750 A-65 with dual 34mm Mukuni’s but compared to the Rickman, it’s was a dog. The Triumph also did what British bikes are famous for: it leaked. Bill was a procrastinator and always meant to work on his bike but just never seemed to get around to it. When he unexpectedly died of heart issues in 1990, I inherited the bike. It had been sitting in his garage unused since 1982. Bill had started an auto parts distribution company which comsumed most of his time and I was a self-employed building and electrical contractor with a new son. We just didn’t have much spare time for our bikes.

I guess life got in the way for me. By the mid to late 1970’s I started riding bicycles on a daily basis before work and on the weekends. The Triumph and BSA just sat in the back of my garage, slowly looking worse each year. I would kick them over once or twice a year and squirt some oil into the cylinders now and then, but mostly they were neglected for various reasons. I always wanted to restore the Rickman and the BSA, and solve their issues but in the last 20 years I have had 17 surgeries and the recuperations involved with them, so I just never got around to it. Almost 4 years ago, I decided that I had waited long enough. I figured the COVID-19 lockdown would be a great time to start this project. My goal was to restore this bike as a street-legal running bike, period correct as much as possible, and stop the oil leaks.

The first thing I found when I started on this project was that the magneto was dead. Zero spark. I took it apart changed the points and condenser and still got no spark. So I sent it off to RebuiltMags.com and Rudy Calin found a couple of issues with it. The coil was installed upside down (this was a used unit) by someone and the armature’s magnet was very weak. He rebuilt it and sent it back to me with a hot spark, which this motor never had. I correctly assumed the hard starting issues would be over. Then I wanted to re-lace the wheels and replace the rusting spokes with stainless steel (SS) ones, so I contacted Buchanan Spokes and bought what I needed. While the wheels were apart I replaced the wheel bearings, front and rear, and bead blasted the front brake. I painted the magnesium front hub, clear-coated the backing plates with high heat paint, and polished the rims and various parts, including the front forks.

There was a tight spot in the drive train when the rear wheel was spun in neutral on a track stand, and this was coming from the transmission. Since the bike never had gaskets “back in the day” but they are available now, this was a good opportunity not only to fix the problem, but also stop some leaking. When I opened up the cases, it was out of oil completely so it took it apart, inspected the gears and shafts, replaced the bearings, thrust washers, seals, etc. from the timing side and put it together with gaskets and Hondabond Sealer on the inner and outer case. A bearing snap ring that hadn’t been seated fully in the bearing, because it was burred, was found to have caused the tight spot.

Then I moved on the next phase of labor, wiring. Originally the bike came with an energy transfer (ET) 6-volt ignition system that also has lighting coils. The ignition had been replaced with the magneto but I would use the 6 volt alternator coils for lighting. It had been quickly wired to pass the DMV requirements but I wanted to do a better wiring job. I placed the wires in a loom, got a high/low beam switch etc., and wired everything in including adding more permanent front and rear stop light switches. Bill had also purchased a larger Rickman fuel tank (about three gallons), which he never got around to installing. I decided to seal both tanks with Caswell Gas Tank Sealer, needed for plastic or fiberglass tanks used with today’s gasoline, which eat up and blister un-sealed tanks and install the larger tank. Along with becoming street legal, the bike needed a kickstand. There might not always be a wall or tree to lean against. A Rickman frame carries the engine oil and is nickel-plated so welding or brazing on to it was out. I decided to weld the kickstand to the painted removable bolt-on foot peg holder, and after some fabrication on the arm, everything worked out well.

The bike was getting close to completion, but I still needed an exhaust system. My original system was VERY unsuccessful from a performance standpoint, and I wanted to avoid another system that would choke this motor’s power. I asked a friend of mine, Bob Stokstad, if he knew someone that welded SS since I had almost no experience with it and knew it could be tricky to weld. My plan was to tack weld together what I needed and have someone else do the welding for aesthetic looks. Bob introduced me to Al Lapp who thought I could do a lot better than just dumping the 1-3/4” pipes into a 45 degree 3” bend. Both Bob and Al had worked for City Bike, a local motorcycle magazine, Bob as a photographer and Al as a graphic artist. My original plan was to use two 45-degree bends and run them into a 3” straight-through SS generic resonator, which I would weld a tab onto. Al instead helped me build a merge collector starting with 1-3/4” SS tubing merging into an oval and then tapering to a round single pipe. It became 7” run or so from the oval into a series of ever larger sections starting at 2-1/4”, then 2-1/2, then 2-/3/4 and then exiting into a 45 degree 3” u-bend before going into my resonator. The tapers were all rolled from 16-gauge flat SS sheet into cones. Al welded a tab onto it, which was supported by a SS bracket that I made which bolted to the engine mounts.

After the original merge collector and first tapered section were built, I would add on sections in my garage by mitering and tacking them for Al to weld. Al introduced me to a product called Solar Flux, Type B, a powder that is mixed with alcohol or Acetone into a paste, and brushed onto the backside of the joint to be welded. Solar Flux-B allows one to TIG weld SS without having to block each end of the pipe and fill it with Argon gas. This method allowed me to build a pair of intermediate short pipes since the TT pipes splayed out to about 4” at the rear of the motor. They needed to be closer and parallel to fit into the merge collector. For some reason the splayed bends in the TT pipes were slightly different so the intermediate pipes were each slightly different and corrected this issue. I made a tab, which Al welded onto the 3” generic SS resonator, and after polishing the finished merge collector, I put the system together. The exhaust system was the most interesting challenge of this build with a great payoff in performance, as each exhaust pulse helps pull the next pulse along.

All the oil was replaced and the bike was ready to fire up. I suspected it would be a little hard to fire up on the first try after 39 years of sitting and oil being squirted periodically into the cylinders, so my electrical partner and friend Mark Malone (we are both retired) pushed the bike to the top of the hill I live on for a bump start. It took a couple of tries but finally it came to life. There was lots of smoke at first but after a couple of minutes and adjustments to the new 34mm Mukuni carburetor, the bike wasn’t smoking any longer and sounded great. It idles beautifully, a little rough from the hot cams, but it’s music to my ears! Mark took it out for its first ride and was blown away by its power. He was able to start it with one kick every time.

It felt great to finally get this bike running and locking so good after so many years of neglect. Other stories and issues arose which are covered in additional articles.

Comments